FIRST-CLASS

Service

Service

DEVELOPMENT & CONSULTING

DEVELOPMENT & CONSULTING

RIGHT FROM THE START

Talk to us if you need advice on plastic processing. We develop both one-stop series products and fully-comprehensive custom solutions, and we manage the entire production chain from development to logistics.

Some of our customers come to us with a specific concept; others just have a basic idea of what they want. Whatever the initial situation, our experienced plastic specialists can provide you with comprehensive advice on implementation options, material properties, production processes and customisation. We team up with you to develop the perfect solution for your requirements.

DESIGN

DESIGN

AS A PROCESS

Our in-house design department is seamlessly integrated into all our processes so that good ideas never fall by the wayside. ROTHE has no efficiency losses resulting from the need to communicate with external service providers.

Our designers are familiar with the comprehensive range of products that our production facilities can manufacture. We transform your ideas into perfect products with our state-of-the-art production equipment – which is directly linked up to our in-house tool engineering department – plus our traditional know-how and our expert knowledge of several thousands of plastic applications.

FAST & FLEXIBLE WITH IN-HOUSE

TOOL ENGINEERING

TOOL ENGINEERING

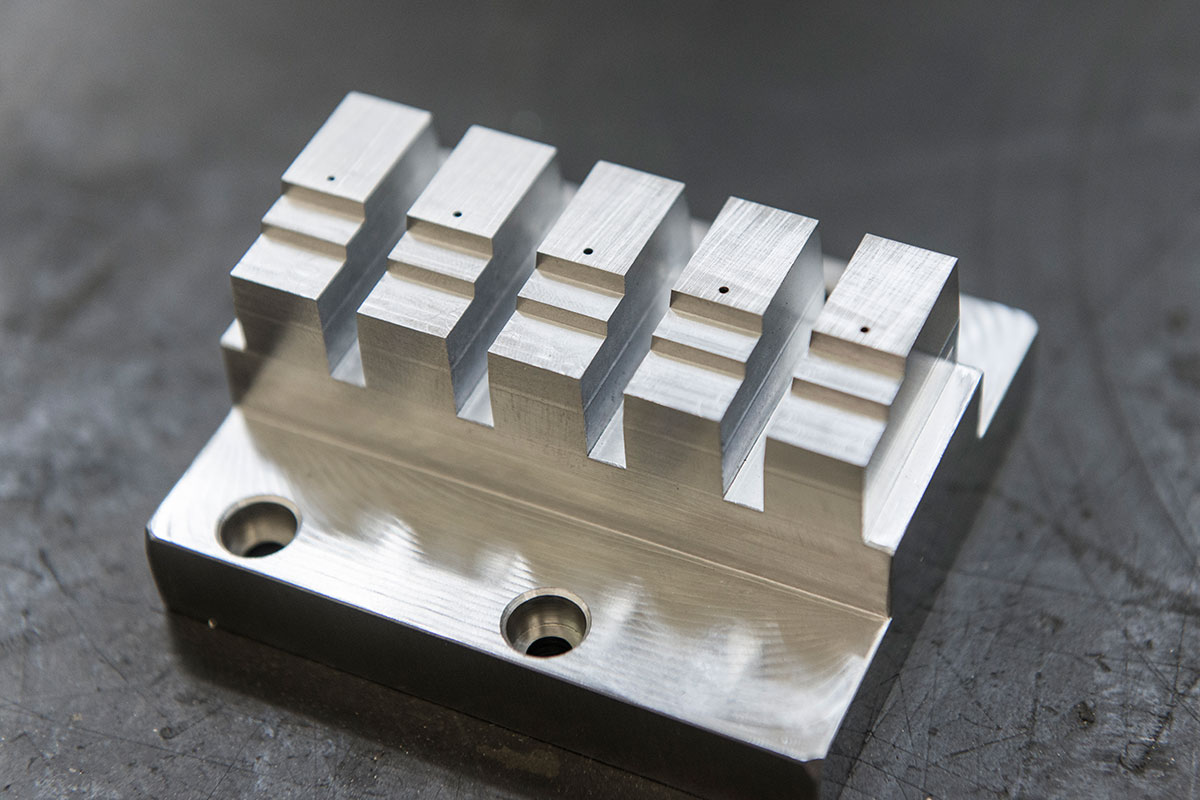

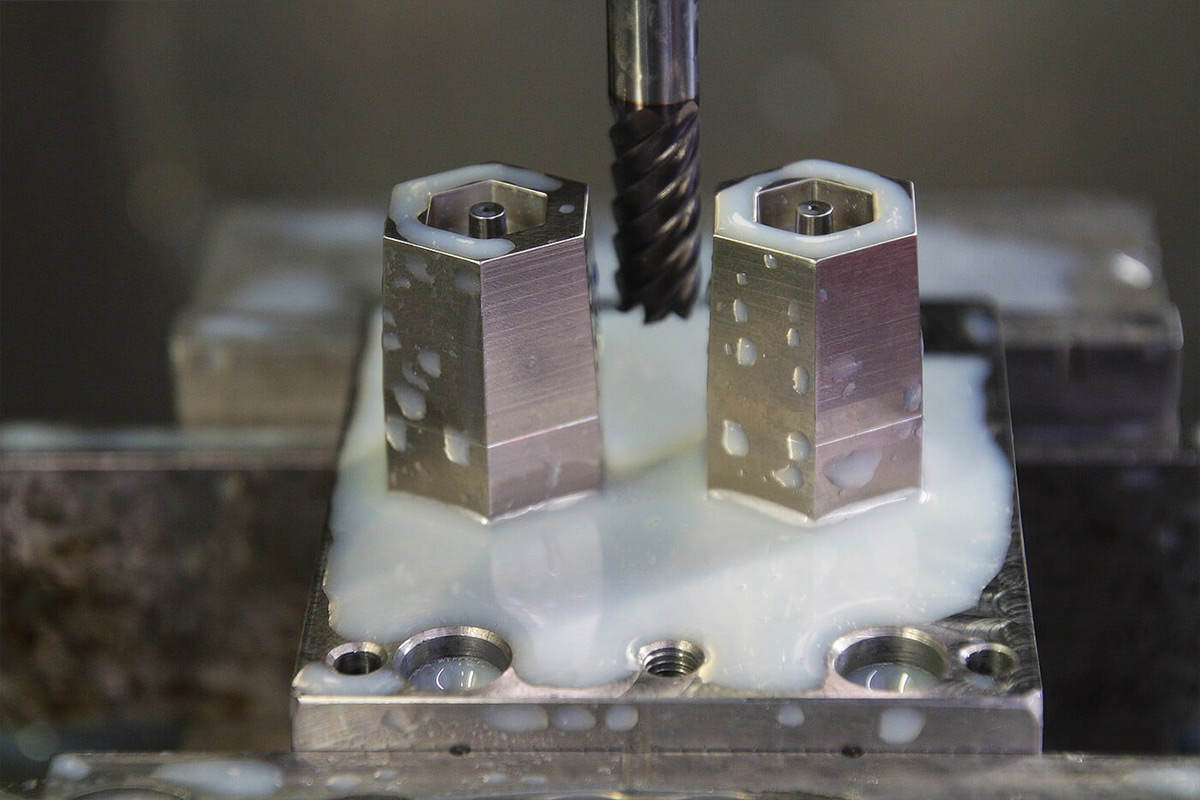

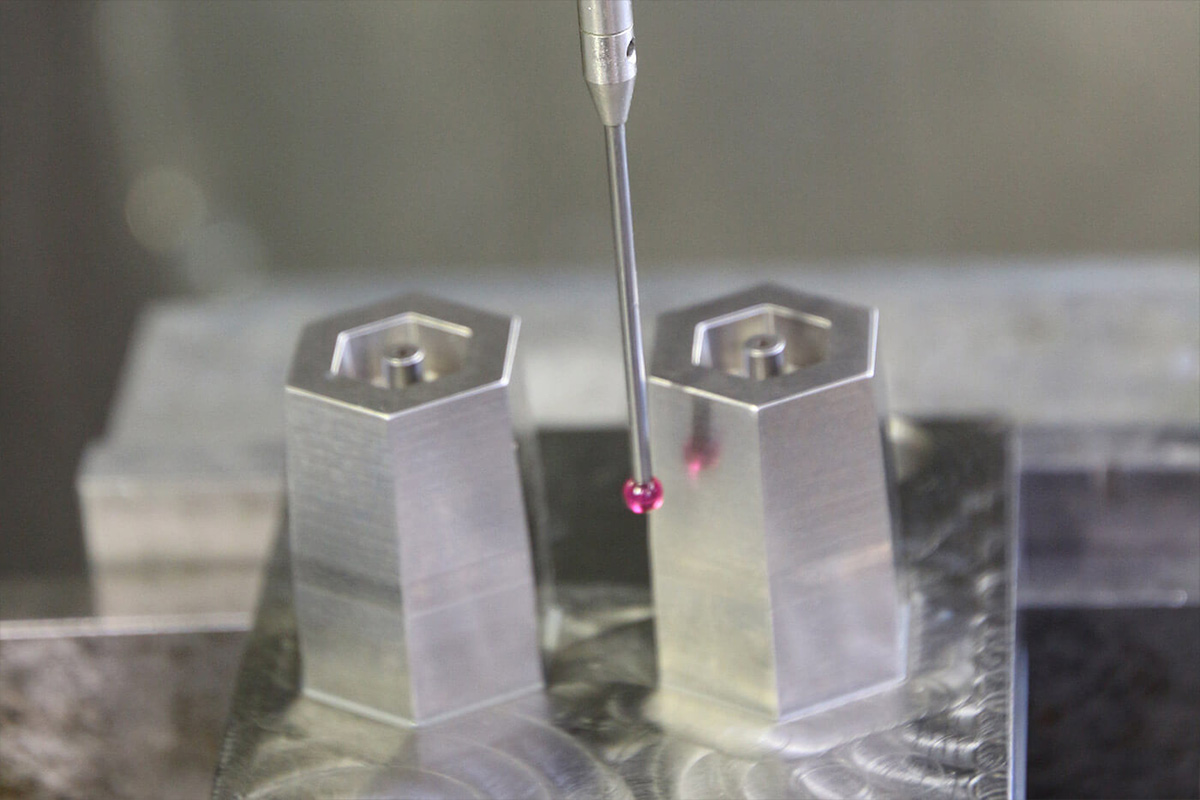

Our in-house tool engineering department’s machines are directly linked up to our designers’ CAD applications. This guarantees impressive flexibility and precise tool implementation. We use a comprehensive range of in-house tool production processes, from lathing and five-axis milling to wire cutting.

Our experienced tool engineers are familiar with all our production machines. They create custom-built tools that are optimised for our production processes and ensure that quality problems and supplier bottlenecks never happen at ROTHE.

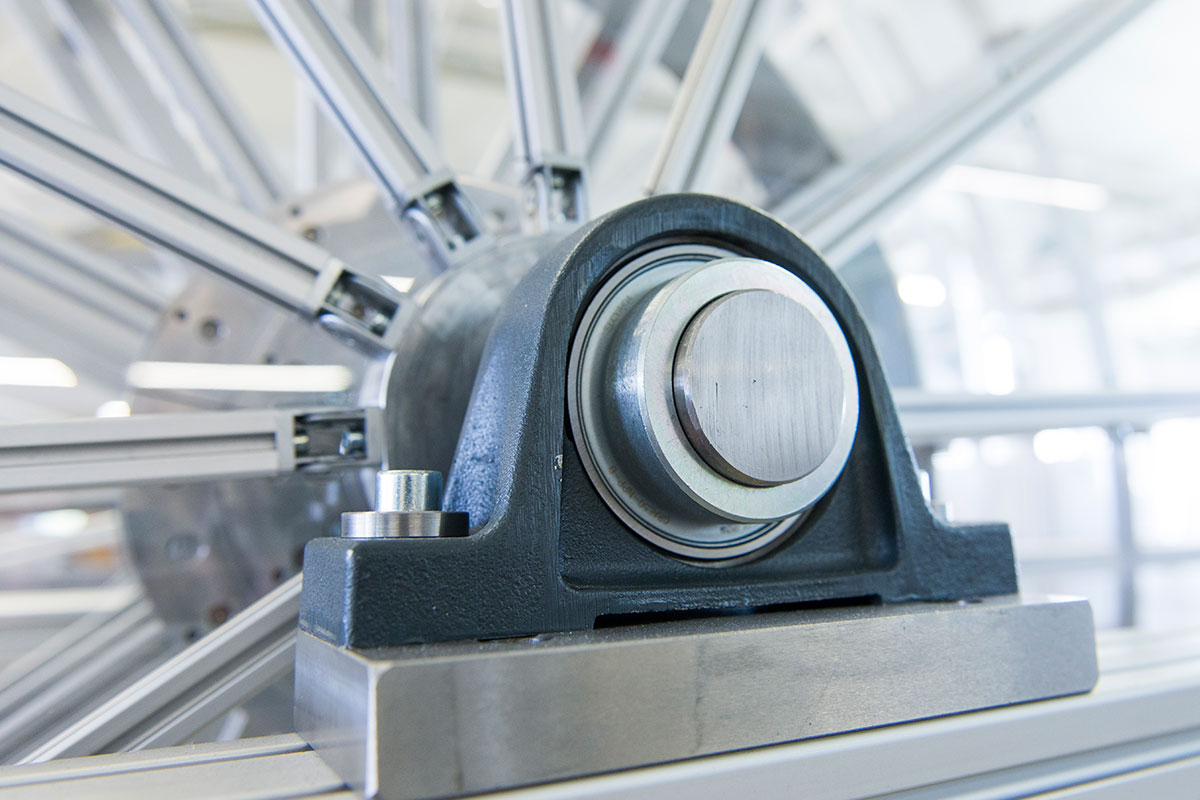

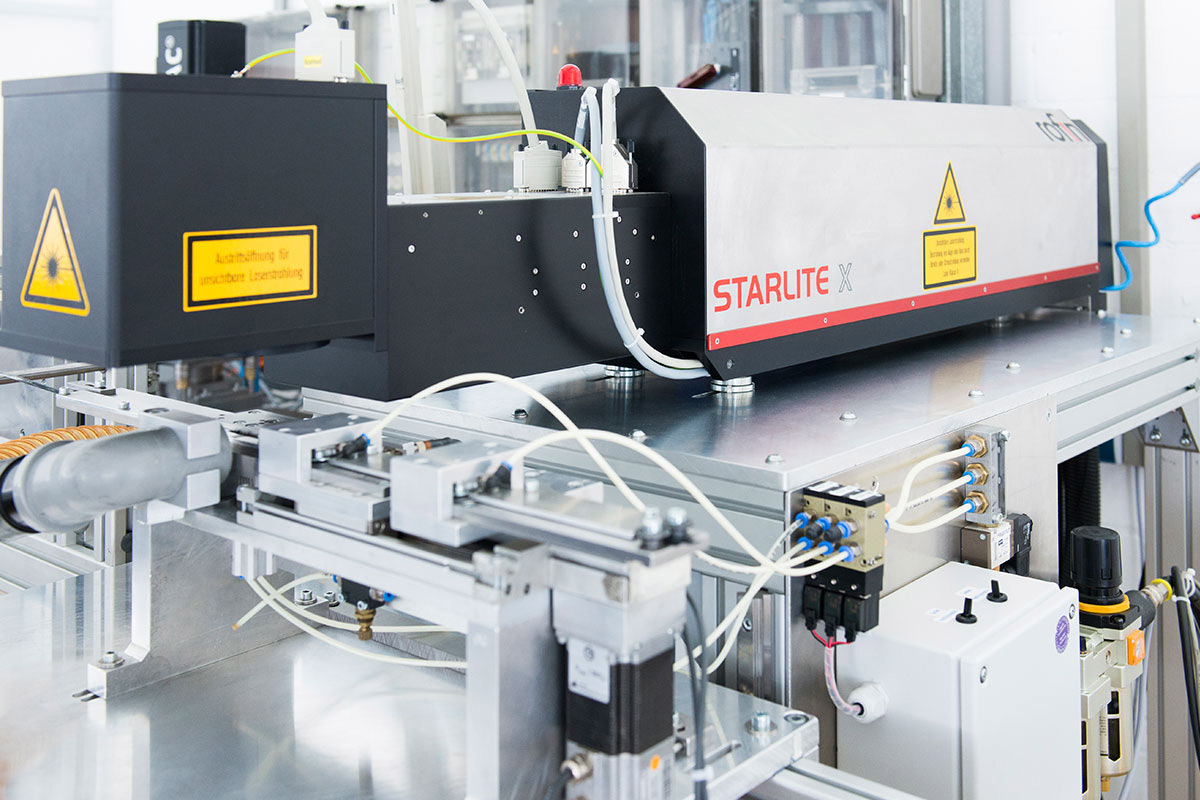

SPECIAL-PURPOSE MACHINE CONSTRUCTION

Standard production equipment isn’t always suitable for custom-made products. When our customers come to us with special requirements, our in-house tool engineering department develops custom-built machines and equipment. You benefit from our direct, in-house retrofitting of production machines because it eliminates the information losses that are associated with external suppliers and we can guarantee fast and optimised production processes.

CUSTOMIZED

LOGISTICS

LOGISTICS

ROTHE is always in the right place at the right time. In Germany, Europe and worldwide, our fast response times and an ultra-modern warehouse guarantee that deliveries to our customers always reach their destination reliably and on time. Our logistics concept is demand-oriented because we are a supplier of fully-comprehensive solutions.

A modern, computer-controlled high-bay warehouse with more than 6000 pallet spaces gives us plenty of scope for flexibility. We can also provide individual warehousing and just-in-time solutions with the help of our efficient logistics partners around the world.

MASS-MANUFACTURED OR

CUSTOM-MADE PRODUCT

CUSTOM-MADE PRODUCT

We deliver fully-comprehensive custom solutions. Depending on your requirements, we can punch, cut, print and package your products.

Printing

The printing process is directly integrated in the production process at ROTHE. This means we can guarantee fast production and response times. We can also comply with special customer requirements of inkjet or tampon printing. The products are printed in a range of colours and the prints – and barcodes, if required – are positioned on the products according to the customer’s specifications.

Punching / cutting

We can provide a range of custom apertures and notches of different shapes and lengths.

Packaging

We package your products in any way you like; either individually, in containers or in special-purpose packaging. You’re very welcome to request a quotation with no obligation, and don’t hesitate to talk to us if you need any advice.