Carrier Tape

Carrier Tape

SYSTEMATIC PACKAGING

Carrier Tape

Carrier Tape

SYSTEMATIC PACKAGING

ROTHE CARRIER TAPE

PRODUCTION

PRODUCTION

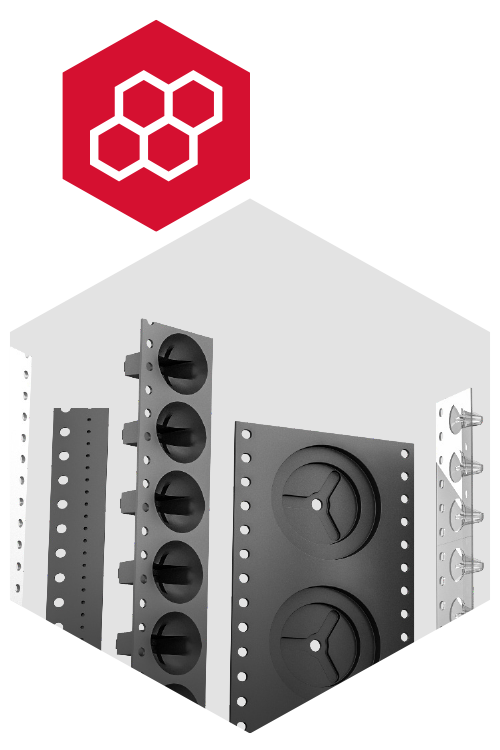

From design to production, tool engineering to logistics, we create your carrier tape system in-house, based on your unique requirements. We develop your products quickly, flexibly, efficiently and reliably using the latest technology. When it comes to smaller volumes, we rely on the tried-and-true linear forming process. The rotation forming process is used for large quantities.

ROTHE PRODUCTION MACHINES

ROTHE PRODUCTION MACHINES

To produce ROTHE carrier tape, we exclusively use specially designed ROTHE production machines, which we continually develop and adapt to individual production requirements. This is how we guarantee the best possible quality with maximum efficiency.

Particles / Dust

Particles / Dust

We have effective, powerful cleaning systems that are directly integrated into the process to ensure the cleanliness of our carrier tape.

Carrier Tape Lenghts

Carrier Tape Lenghts

The optimal carrier tape length is based on the reel type and cavity shape and, if necessary, your specific requirements. We deliver as standard in fixed lengths either on single-track or cross-winding reels. This means our customers always have the same packaging units for optimal production planning. Of course, you can also purchase variable lengths. For critical cavity shapes, we use a head winding and/or interlayer paper.

Norms / Standards

Norms / Standards

Our carrier tapes meet all relevant international standards, e.g. DIN IEC 60286-3, EIA 481-E. We also manufacture custom tapes according to your specifications.