TRADITION, QUALITY, ENVIRONMENT

About ROTHE

as a company

About ROTHE

as a company

ROTHE looks back on many years of experience and tradition. ROTHE was founded in Chemnitz in 1907. After the end of the war, the company moved locations to Königheim and began processing thermoplastic films. The location changed again in 1964, this time to Kitzingen. The product range expanded to include injection moulding and extrusion. ROTHE was one of the first producers of thermoformed carrier tapes. Today we are one of the largest European manufacturers in the sector. You can rely on our years of experience and knowledge in plastics processing. Whether you are looking for a standard system or a complex individual solution, we are the partner you need.

MADE IN GERMANY

TOP QUALITY

TOP QUALITY

The name ROTHE stands for certified quality. Our sophisticated quality management system ensures the highest-possible levels of quality – from development, to production, to delivery. All processes are certified according to DIN ISO 9001.

This is how we guarantee consistent quality. With our state-of-the-art monitoring methods, including optoelectronic tests and in-line production controls, we ensure that our products meet the most demanding requirements and standards.

Design

Department

Customised packaging for your components – our design department is up to any challenge

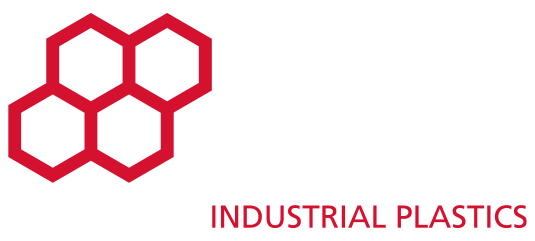

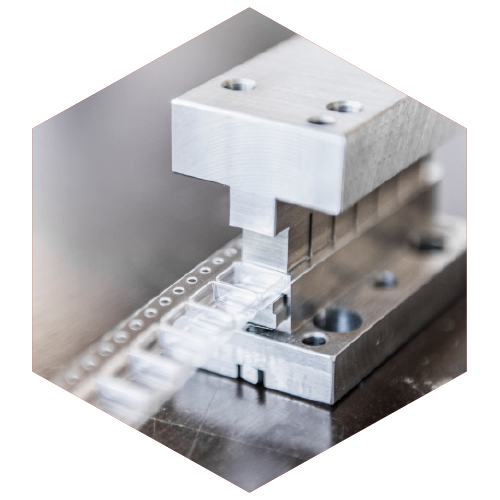

Tool engineering &

custom machine construction

Fast and flexible – excluding quality problems/bottlenecks due to external service providers

High-Tech

logistics warehouse

ERP-controlled high-bay warehouse with more than 6000 pallet spaces

INVESTMENTS IN THE FUTURE

Environmentally

friendly production

Environmentally

friendly production

We take our responsibility towards future generations seriously and use only environmentally friendly processes when processing plastics. Rothe does not use chemicals that are harmful to people’s health or to the environment. And that has been the case for years.

Production

Our exclusively electronic production machines have enabled us to significantly improve our efficiency and energy consumption.

Heat recovery

systems

Heat recovery on heat-intensive machines provide support for operational heating.

Photovoltaic

system

450 kWp systems to support production facilities.

Recycling

In some areas of production, we are already manufacturing over 95% of our products from recycled plastic.

We happily accept sorted industrial waste

We send our waste and client waste to recycling as much as possible.

A LOOK AT OUR